Welcome! If you’re searching for the best iron for edge banding, look no further. Choosing the suitable iron for this process ensures precise application and long-lasting results. In this guide, we will explore a selection of top-notch irons. It excels in heat control, ease of use, durability, and effectiveness in creating seamless edge banding. Whether you are a professional woodworker or a passionate hobbyist, we have you covered. Let’s get started and find your perfect edge banding iron!

Table of Contents

Top 7 Edge Banding Irons for Precision Work

1. BLACK DECKER Easy Steam Compact Textile Iron

Introducing the best edge banding iron equipped with advanced features for optimal results. This edge banding iron is designed with intelligent technology that automatically regulates the amount of steam based on the temperature setting. This proprietary technology streamlines controls and ensures perfect results every time.

The 3-Way Auto Shutoff feature provides peace of mind with motion-sensitive technology. If the iron is inactive on its heel, side, or soleplate, it will automatically shut off. This convenient feature eliminates the need to check if the iron has been turned off constantly.

Engineered with Anti-Drip technology. This edge banding iron prevents any dripping. It maintains water at the proper temperature needed to generate steam, ensuring a seamless ironing experience. The true glide nonstick soleplate enhances the performance of this iron. Designed to glide smoothly across all of it, provides ease of use and effortless ironing.

This edge banding iron is specially designed with a lightweight feature that provides easy maneuverability. With its compact item dimensions of 10.4 x 4.38 x 5.8 inches.

The iron also features an auto shutoff function for added safety. Not only is this edge banding iron user-friendly, but it also offers exceptional durability. It is built to withstand frequent use and provide long-lasting performance. With a wattage of 1200 watts, it delivers efficient results and ensures a smooth and seamless finish.

Invest in the best iron for edge banding that combines SmartSteam Technology, 3-Way Auto Shutoff, Anti-Drip, TrueGlide Nonstick Soleplate, and Spray Mist. Experience ultimate comfort and efficiency in your ironing routine. Its durability makes it the ideal tool for faster and more precise edge banding projects.

Pros

- Smart Steam Technology for optimal results.

- 3-Way Auto Shutoff for added safety.

- Anti-drip technology for a seamless ironing experience.

- True Glide Nonstick Soleplate for effortless ironing.

Cons

- Limited size with compact dimensions.

2. Rowenta Access Stainless Steel Soleplate Steam Iron

This edge banding iron has been designed with user-friendly features and built to deliver exceptional results. Easy setup is ensured by the retractable cord. Convenience in both usage and storage is provided through tangle-free storage.

When it comes to ironing, this product excels in steam diffusion. With over 350 micro-holes, it provides powerful and efficient steam distribution. Durability is a key feature of this edge banding iron. Made with high-quality stainless steel and exceptional engineering. It is built to withstand daily use and deliver consistent performance. This ensures that the iron maintains its functionality and effectiveness over time. Allowing you to rely on it for all your edge banding needs.

This Rowenta edge banding iron with a retractable cord of 1725 watts of power is the best choice for high-quality edge banding. Its ultimate steam diffusion, durable construction, and user-friendly features make it an excellent option for both professions.

Its sleek and modern design not only looks great but also makes it easy to handle and maneuver.

This edge banding iron is a lightweight construction, which makes it incredibly easy to use and maneuver. You won’t have to worry about fatigue or strain, even during long ironing sessions. With its advanced safety features, you can confidently leave the iron unattended knowing that the auto-off feature.

Say goodbye to all hassle and hello to perfectly edge banding. It will be the best iron for edge banding. Whether you’re a professional or just someone who takes pride in their appearance, this iron is the perfect tool to have in your arsenal. Experience the convenience, safety, and superior results that this iron offers.

Pros

- User-friendly features and easy setup with retractable cord.

- Powerful and efficient steam diffusion with over 350 micro-holes.

- Durable construction made with high-quality stainless steel.

Cons

- May be more expensive compared to other steam irons on the market.

- Some users may find the iron’s sleek and lightweight design to be less sturdy or stable compared to heavier models.

3. O’SKOOL Display Veneer Edge Banding Iron

The O’SKOOL Best Edge Banding Iron is made from high-quality PTFE+TPR material, ensuring durability and longevity. Its rectangular shape allows for easy maneuverability and precise edge banding.

This edge banding iron includes a 110V cord, safety metal stand, cotton sock, and operating instructions. Providing everything you need for efficient and safe operation.

The precise thermostatic control of this iron ensures accurate temperature adjustments ranging from 100°C to 200°C (±10°C) or 212°F to 392°F (±18°F). The LCD screen displays the current temperature, guaranteeing precise and reliable readings.

With the touch of a button, you can easily change the temperature setting, allowing for seamless transitions between °C and °F measurements. By holding the (ON ⁄ OFF) & (°C/°F) button for approximately 3 seconds, you can effortlessly switch between temperature scales.

This exceptional product features an ergonomically designed handle for superior user comfort and control. With specially designed tips, it effortlessly tackles fillets, curves, and corners. Allowing easy access to even the tightest spots.

Experience the convenience and versatility of the O’SKOOL which is best iron for Edge Banding. Providing professional-grade performance for all your edge banding needs.

Pros

- Made from high-quality materials, ensuring durability and longevity.

- Precise thermostatic control allows for accurate temperature adjustments.

- Ergonomically designed handle provides superior comfort and control.

Cons

- The product requires an electrical outlet to operate.

- The LCD screen may be difficult to read in certain lighting conditions.

4. Rowenta Pro Compact Stainless SteelSoleplate Steam Iron

The best edge banding iron features a compact yet powerful design. With a 1000-watt iron and micros team durable stainless-steel soleplate, it provides efficient and durable performance.

The versatile design allows the iron to be used with or without steam and works with tap water, eliminating the need for distilled water. The large transparent water tank makes it easy to monitor the water level.

A sleek handle folds for travel storage, and a travel pouch is included for convenience. The iron also has a dual-voltage system, allowing it to work on both 120V and 230V. The iron’s small details, such as its precision tip, are designed to smooth collars, seams, and narrow edges.

Additional features of the iron include adjustable temperature, consistent steam, and a burst-of-steam button. It also offers a vertical-steam option for versatile use. The compact size of the iron and the folding handle make it easy to store and travel with. A travel pouch is included for added convenience.

The iron has a 2-ounce transparent water tank, ensuring an ample supply of steam. It also has a dual-voltage switch, allowing it to be used with different voltage standards (120-240 Volts). What sets this iron apart is its highly polished Microsteam 200 stainless steel soleplate. With 200 steam holes, it offers superior steam distribution and glides smoothly across the fabric. The high-precision tip enables easy maneuverability in pleats, between buttons, and along seams.

With its compact yet powerful design, efficient performance, and versatile usage options, it makes a big difference. This edge banding iron is the perfect choice for all your ironing needs.

Pros

- Compact yet powerful design.

- Efficient and durable performance.

- Versatile usage options.

Cons

- It May require a voltage adapter for international use.

5. Sunbeam Steam master 1400-Watt Steam Iron

Introducing the Sunbeam Best Edge Banding Iron. With its special nonstick feature, you can glide seamlessly through fabrics without any snagging or sticking. In a sleek chrome and teal color combination, this iron adds a touch of style to your ironing routine. It is also equipped with a powerful 1400-watt motor, ensuring faster heating and saving you precious time.

One of the standout features of this iron is its powerful shot of steam function. Whether you’re dealing with hanging garments, upholstery, or drapery, this iron can deliver a burst of steam horizontally or vertically to smooth out even the toughest creases. The spray mist feature is another handy addition that helps to further eliminate wrinkles.

Simply spray a fine mist over your garments and watch as the iron effortlessly smooths them out. It features a large stainless steel nonstick soleplate. This iron glides smoothly across fabrics, making your ironing experience effortless and efficient. No more worrying about sticky residue.

Safety is a top priority with the Sunbeam Best Edge Banding Iron. It is equipped with an auto-shut-off feature, which engages after three minutes of inactivity. This gives you peace of mind if you accidentally leave the iron unattended. It will automatically turn off for added safety.

The large tank, no leaks, no worry feature includes a spacious 240ml water tank ensuring mess-free ironing sessions. The iron’s self-cleaning function effectively removes mineral buildup, guaranteeing excellent performance over time. Lastly, this product comes with a 3-year limited warranty. Providing you with peace of mind and confidence in your purchase.

Pros

- Nonstick feature for seamless gliding through fabrics.

- Powerful shot of steam function for tackling tough wrinkles.

- Auto shutoff feature for added safety.

Cons

- Limited tank capacity at 240ml.

- Requires regular self-cleaning to maintain performance.

6. Wood River Digital LCD Display Veneer Edge Banding Iron

The best edge banding iron is from the brand WOOD RIVER and comes with a special feature of temperature control. With a wattage of 1500 watts, this iron ensures efficient and powerful performance. The item dimensions measure at 15.1 x 3.5 x 2.4 inches, making it compact and easy to handle.

This iron features a digital LCD display that clearly shows the temperature setting for user convenience. This enables precise digital temperature control ranging from 100°C to 220°C (212°F – 428°F), ensuring accurate and consistent results. Users can easily toggle between °C and °F to accommodate their preferred temperature unit. The product comes with a 4′ 9″ power cord that operates on 110V, providing ample reach for various workspaces. As a safety measure, the iron includes an automatic shutoff feature after six hours. That’s giving users peace of mind.

This edge-banding iron offers unparalleled versatility and control. Its ergonomic handle provides a comfortable grip. The adjustable temperature control feature enables you to customize the heat settings according to the specific requirements of your project. It ensures superior bonding of the edge banding tape.

Equipped with advanced heating technology, this iron heats up quickly. It distributes heat evenly across the surface. The smooth and flat ironing plate optimizes the adhesion of the edge banding, ensuring a seamless bond with the wood. Its compact size and lightweight design make it portable and easy to maneuver. It is best for effortless edge banding on various woodworking projects.

Pros

- Temperature control feature.

- Digital LCD display for easy temperature monitoring and adjustment.

- Compact and lightweight design for portability and maneuverability.

Cons

- An automatic shutoff feature after six hours may not be ideal for longer projects.

7. Steam fast SF-710 Mini Steam Iron

One of the standout features of this iron is its quick heat-up time. With just a 1-ounce water tank, it heats up in a mere 45 seconds, allowing you to get to work swiftly. It is equipped with a temperature control dial. A steam burst button and dry or steam iron settings ensure compatibility with various edge types.

With its quick heat-up time and powerful 800-watt motor, this iron is equipped to handle any job with ease. Equipped with four steam outlets, this iron provides a continuous flow of steam for effortless wrinkle removal. Whether you’re working with delicate fabrics or heavy-duty materials, this iron has the power to deliver exceptional results.

Designed with convenience in mind, this iron features a collapsible handle that allows for easy travel. The included measuring cup ensures precise water filling, adding to the overall convenience of this product.

Not only does steam effectively remove wrinkles, but it also freshens fabric without the need for harsh chemicals. With this iron, you can be confident that you’re caring for your fabrics in a safe and natural way.

When you choose the steam-fast corded edges banding iron, you’re investing in a product that guarantees superior performance and design. And if for any reason you’re not completely satisfied, it offers a 2-year replacement warranty. Plus, the customer service team is based in Andover, KS, ensuring that you’ll receive the support you need.

Please note that this iron is built to meet U.S. voltage requirements and is certified and safety-tested for use in the U.S. only.

Pros

- Quick heat-up time of just 45 seconds.

- Equipped with temperature control dial and steam burst button for versatility.

Cons

- A small 1-ounce water tank may require frequent refills.

- Designed for use in the U.S. only, not compatible with international voltage requirements.

Buying Guide for Best Iron for Edge Banding

Buying a good iron for edge banding is crucial to achieving professional and durable results. Here are some key factors to consider when selecting the best iron for edge banding.

Temperature Control

Look for an iron with adjustable temperature settings. Different types of edge banding materials require different temperatures for optimal bonding. Having the ability to control the temperature ensures that you can achieve the perfect heat for your specific application.

Heat Distribution

A good iron should have even heat distribution across the soleplate to ensure consistent bonding. Look for irons with a flat and wide soleplate, as it will provide better contact and heat distribution on the edge banding material.

Soleplate Material

The soleplate material is an essential consideration. Teflon-coated or stainless steel soleplates are commonly used for edge banding as they provide smooth gliding and prevent the adhesive from sticking. They are also easy to clean, which is important for maintaining the iron’s performance.

Power and Wattage

Higher-wattage irons tend to heat up faster and maintain a more stable temperature during use. Ensure the iron you choose has sufficient wattage for your specific edge banding needs.

Ergonomics

Look for irons with comfortable handles and lightweight designs. Edge banding can be a time-consuming process, so having a comfortable and easy-to-use iron will make the job less tiring.

Safety Features

Safety is crucial when working with hot irons. Look for irons with features like automatic shutoff after a certain period of inactivity, heat-resistant handles, and a stable base that prevents accidental tipping.

Cord Length

Make sure the iron has a long enough cord to provide flexibility and reach all areas of your work surface.

Durability and Quality

Invest in a high-quality iron that is built to last. Look for irons from reputable brands with positive customer reviews and warranties.

Price

While price shouldn’t be the only factor to consider, it’s essential to find a balance between quality and affordability. Set a budget and choose an iron that offers the best value for your money.

Customer Reviews

Read customer reviews and ratings to get an idea of other people’s experiences with the iron you’re considering. Look for feedback on heat control, heat distribution, durability, and overall performance.

By considering these factors, you can find the best iron that meets your requirements and helps you achieve professional results.

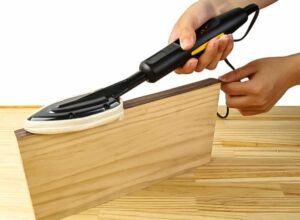

Best Technique for Iron on Edge Banding and Amazing 5 Tips

1. Measure and cut the edge banding slightly longer than the length of the edge you are applying it to. This will give you some room for adjustment and prevent any gaps or unevenness.

2. Use a heat gun or iron on the lowest setting to gently heat the edge banding. This will soften the adhesive and make it easier to attach to the edge.

3. Use a smooth, flat surface such as a wooden block or metal straight edge to apply pressure to the edge banding as you heat it. This will help ensure a secure bond and prevent any bubbles or wrinkles.

4. Work in small sections, applying the edge banding one section at a time. This will prevent the adhesive from drying out or cooling off before you have a chance to attach it.

5. Trim off any excess edge banding using a sharp utility knife or trimmer. Be sure to cut at a slight angle to create a smooth, seamless edge.

Here is the practical video :

A Guide to Different Types of Edge Banding Iron and Their Uses

Standard Edge Banding Iron

This is the most common type of edge banding iron used by DIY enthusiasts and professionals. It features a flat, heated metal plate for applying heat and pressure to the edge banding material.

Terms of Use

1. Prepare the edge of the wood material by sanding it smooth and free of any imperfections.

2. Measure the length of the edge that needs to be covered with the edge banding material.

3. Cut a piece of edge banding material that is slightly longer than the measured length.

4. Place the edge banding iron on a stable surface and plug it into a power source to preheat for about 5-10 minutes.

5. Place the edge banding material over the edge of the wood, ensuring it is centered and aligned correctly.

6. Hold the edge banding material in place with one hand while bringing the preheated edge banding iron in contact with the material.

7. Apply gentle pressure and slowly move the edge banding iron along the length of the material. Melting the adhesive on the back of the edge banding.

8. Make sure to keep the edge banding iron moving constantly to prevent overheating or burning the edge banding material or the wood surface.

9. Continue heating and pressing the edge banding material until it is securely bonded to the wood edge.

10. Use a roller or a wood block wrapped in a cloth. Ensure even pressure and firmly bond the edge banding material to the wood.

11. Trim any excess edge banding material using a utility knife or edge trimmer. Be careful not to damage the wood surface.

12. Use a file or sandpaper to smooth out any rough edges or uneven surfaces.

13. Clean the edge banding iron and any leftover adhesive from the surface of the wood with a cloth or adhesive remover.

14. Allow the edge banding to cool and fully set according to the manufacturer’s

instructions before handling or applying further finishes to the wood.

Specialized Edge Banding Iron

This type of iron is designed specifically for certain types of edge banding materials, such as PVC or wood veneer. It may have adjustable temperature settings and a specific shape or surface texture for optimal adhesion.

Terms of Use

1. Ensure that the edge banding material is the correct size and type for your project.

2. Plug in the specialized edge banding iron and allow it to heat up for the recommended amount of time, usually around 10 minutes.

3. Use a utility knife to trim the excess edge banding material from the edges of your project so that it is flush with the surface.

4. Hold the edge banding iron at a slight angle and press it firmly against the edge banding material. Start at one end of the edge and slowly work your way to the other end, applying even pressure along the entire length.

5. Move the edge banding iron back and forth along the edge, melting the adhesive and bonding the edge banding material to the surface. Take care not to hold the iron in one place for too long, as this can cause the material to burn or discolor.

6. Use a roller or a block of wood wrapped in a cloth to apply additional pressure to the edge banding material, ensuring a strong bond with the surface.

7. Allow the edge banding material to cool and set for the recommended amount of time, usually around 30 minutes.

8. Once the edge banding material has been fully set, use a sander or sandpaper to smooth out any rough edges or uneven surfaces.

9. Apply any desired finishes or sealants to the edge banding material to match the rest of your project.

10. Clean the specialized edge banding iron after use, following the manufacturer’s instructions, to ensure its longevity and proper functioning for future projects.

Air Edge Banding Iron

An air edge banding iron uses compressed air to heat the metal plate instead of electricity. This type of iron is often used in industrial settings or for large-scale projects where quick and consistent heat application is required.

Terms of Use

1. Ensure that the Air Edge Banding Iron is plugged into a properly grounded electrical outlet.

2. Set the desired temperature for the banding iron. This can usually be adjusted using a dial or control on the iron itself.

3. Allow the banding iron to heat up to the desired temperature. This typically takes a few minutes.

4. While waiting for the iron to heat up, prepare the banding material by trimming it to the appropriate length and width for your project.

5. Place the trimmed banding material onto the edge of the surface you wish to edge the band. Make sure it is aligned properly and covers the intended area.

6. Once the iron has reached the desired temperature, gently press the heated metal surface of the iron onto the banding material. Apply even pressure as you move the iron along the length of the material.

7. As the iron passes over the banding material, the heat will activate the adhesive backing on the material, causing it to bond with the edge of the surface.

8. Continue moving the iron along the entire length of the banding material, ensuring proper adhesion. Take care to maintain a consistent temperature and pressure throughout the process.

9. After completing the banding process, allow the material to cool and bond completely before continuing with any additional finishing or sanding of the project.

10. Clean the Air Edge Banding Iron after use by wiping off any excess adhesive or residue. Ensure that the iron has cooled down completely before storing or packing it away.

Handheld Edge Banding Iron

This compact and portable iron is designed for smaller edge banding projects or for working in tight spaces. It typically has a smaller heating plate and may have a cordless or rechargeable battery option for added convenience.

Terms of Use

1. Prepare the edge banding material by cutting it to the desired length and applying any necessary adhesive to the backside.

2. Set the handheld edge banding iron to the appropriate temperature for the type of edge banding material you are using. Refer to the manufacturer’s instructions for specific temperature recommendations.

3. Plug in the handheld edge banding iron and allow it to heat up for the recommended amount of time.

4. Position the edge banding material along the edge of the workpiece, ensuring that it is aligned properly and any excess material is trimmed away.

5. With the handheld edge banding iron fully heated, apply firm and even pressure to the edge banding material as you run the iron along the length of the edge. This will activate the adhesive and bond the edge banding to the workpiece.

6. Repeat this process for all edges requiring edge banding, taking care to maintain consistent pressure and speed to ensure a smooth and even bond.

7. Once all edges have been banded, allow the adhesive to cool and set according to the manufacturer’s instructions.

8. Trim any excess edge banding material using a trimmer or utility knife, following the contour of the workpiece.

9. Sand the edges lightly to remove any rough edges or imperfections.

10. Clean and maintain the handheld edge banding iron regularly to ensure its proper functioning and longevity. Follow the manufacturer’s instructions for cleaning and maintenance guidelines.

Cold Edge Banding Iron

As the name suggests, a cold edge banding iron does not use heat to activate the adhesive on the edge banding material. Instead, it uses mechanical pressure, such as a rolling or squeezing motion, to bond the edge banding to the substrate.

Terms of Use

1. Start by selecting the cold edge banding iron with the appropriate width for your banding tape.

2. Plug in the cold edge banding iron and allow it to heat up for the recommended amount of time, usually indicated in the user manual.

3. While waiting, clean the surface where the banding tape will be applied to ensure a smooth and adhesive-friendly surface.

4. Once the cold edge banding iron has heated up, grip it by the handle and position the heated plate on the banding tape, applying gentle pressure.

5. Slowly glide the cold edge banding iron along the length of the banding tape, applying a consistent and firm pressure.

6. Be cautious not to leave the cold edge banding iron on one spot for too long, as this may cause the tape or the material underneath to burn or warp.

7. Ensure that the banding tape is securely adhered to the surface by gently running your finger or a roller over it, removing any air bubbles or wrinkles.

8. Once the banding tape is fully adhered, allow it to cool down for a few minutes before sanding or trimming any excess material.

9. Use a sharp utility knife or special edge trimming tool to trim the excess banding tape, cutting it flush with the edge of the surface.

10. Use sandpaper or a file to smooth out any rough or uneven edges, ensuring a clean and seamless finish.

11. Clean the cold edge banding iron after use by unplugging it and allowing it to cool down completely. Use a damp cloth to wipe away any residue or adhesive buildup.

12. Store the cold edge banding iron in a safe and dry place, away from excessive heat or moisture.

13. Follow the manufacturer’s instructions and safety precautions at all times when using the cold edge banding iron.

Why Is Sometimes Iron on Edge Banding Not Sticking?

There can be several reasons why your iron-on-edge banding is not sticking properly.

1. Insufficient heat

Make sure that the iron is set to the correct temperature for applying edge banding. If the iron is not hot enough, the adhesive on the edge banding may not fully activate and bond.

2. Inconsistent pressure

Apply even pressure across the entire length of the edge banding using the iron. If there are areas where less pressure is applied, the adhesive may not fully adhere.

3. Poor surface preparation

The surface where the edge banding is being applied should be clean, smooth, and free from dust or debris. If the surface is not properly prepared, the adhesive may not bond properly.

4. Incorrect adhesive

Different edge banding products have different types of adhesives. Make sure that you are using the correct type of edge banding adhesive for your particular material.

5. Low-quality or expired edge banding

If the edge banding material is old or of poor quality, the adhesive may not work effectively. It is essential to use high-quality edge banding from reputable manufacturers.

If you have checked all these factors and the edge banding still does not stick, it may be necessary to consider other methods of adhering the band, such as using a different type of adhesive or trying a different brand of edge banding.

Frequently Asked Questions Answered

1. How Hot Should Iron Be for Edge Banding?

It is recommended to set the iron to a medium heat setting between 250-300 degrees Fahrenheit (121-149 degrees Celsius). It is always advisable to refer to the manufacturer’s instructions for the specific type of edge banding material you have.

2. How Thick Is Iron on Edge Banding?

The thickness of iron on edge banding can vary, but it is typically around 0.5mm to 2mm thick. However, there may be different thickness options available depending on the specific brand and type of edge banding chosen.

3. What Is the Standard Size of Iron for edge banding?

The standard size of iron for edge banding is typically around 1 inch (25mm) wide and 6 inches (150mm) long.

4. What Is the Best Material for Edge Banding Iron?

The best material for edge banding iron is generally considered to be Teflon or PTFE (Polytetrafluoroethylene). Teflon has excellent heat resistance and nonstick properties. It’s

ideal for use with hot adhesive and preventing it from sticking to the iron. It also helps to provide a smooth and clean finish to the edge banding process.

5. What Is the Most Durable Edge Banding Iron?

One of the most durable and highly recommended edge banding irons is the Bosch PR20EVSNK Colt Palm Router and Edge Guide. This edge banding iron is known for its robust construction and superior durability. It is designed to handle heavy-duty applications and provide long-lasting performance. It offers precise control and accuracy during edge banding tasks, making it a top choice among professionals and DIY enthusiasts.

Conclusion

After thoroughly researching and analyzing various iron options for edge banding, it is clear that there are several top contenders in the market. The best iron for edge banding are those that exhibit a combination of durability, versatility, and efficiency. These irons not only produce high-quality results but also ensure ease of use and long-lasting performance. Considering these factors, it can be concluded that the best iron for edge banding.