Clamping squares are designed to be durable and provide a precise 90-degree angle for accurate and secure clamping. These squares feature a sturdy construction and come in various sizes to accommodate different project needs. With their reliable clamping mechanism, these squares allow for quick and efficient woodworking tasks. Whether you are building cabinets, shelves, or frames, invest in the best clamping squares. It will ensure your projects are perfectly square and professionally finished.

Table of Contents

Ultimate Guide to Finding the Best Clamping Squares

1. Deadwood Crafted Tools Right Angle Clamp Set

These clamping tools are made with a combination of high-quality plastic and durable metal materials. These woodworking tools are designed to make completing woodworking projects easier and more efficient.

With the two-pack large right-angle Clamp, you can securely hold and glue together two stock pieces. They are especially useful for any project. The squares are designed to fit wood boards that are between 7/16 to 1-9/16 inches thick.

It comes with inch increments on one arm and millimeter increments. On the other hand, ensuring precise and accurate measurements. Each wood square tool measures 6.3 by 6.3 inches or 160 x 160mm, allowing you to work with various sizes of wood pieces effortlessly.

When it comes to quality, you can trust this 90-degree clamps woodworking jig set. Constructed of aluminums alloy, these clamps are built to last. The stainless-steel clamps offer strong hold power and optimal balance so that your wood pieces are exactly level.

The package includes two metal L-style wood clamps, four plastic nuts, four adjusted fixed blocks, and four right-angle screws. Once assembled, you will have two corner squares and four clamps ready to assist you in achieving perfect joints and corners.

Say goodbye to wobbly and uneven wood pieces with these woodworking cabinet clamps.

Pros

- Made with high-quality plastic and durable metal materials.

- Comes with precise and accurate measurements.

Cons

- Limited to fitting wood boards between 7/16 to 1-9/16 inches thick.

- Assembly required to use the clamps effectively.

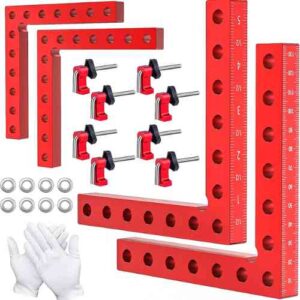

2. Mikego 90 Degree Clamp

This woodworking precision 90-degree angle clamp is a must-have tool for any woodworker. Made of high-quality aluminums alloy, this clamp ensures precise 90-degree angles. Its anodized red surface is anti-rust and corrosion-resistant, making it a durable and long-lasting tool. The CNC processing further enhances its durability.

Operating this clamp is a breeze. The square clamp “L” edge is chamfered to ensure a smooth and soft surface that will not scratch your hands or wooden products. Simply place the positioning squares on the corners of the woodwork.

Secure them with the included clips to achieve a perfect 90-degree angle. This easy-to-use clamp securely holds the pieces together, making your woodworking projects hassle-free.

The clamp’s size, measuring 5.5″ x 5.5″ (140mm x 140mm), makes it suitable for various applications. It is ideal for assembly and DIY projects such as photo frames, drawers, cabinets, furniture cabinets, birdhouses, and mailboxes. It is also great for organizing shelving cabinets.

This tool is designed to clip onto most types of boxes, aiding in levelling them during glueing or splicing. It can also be used with jigs to inspect and position plank seams for glueing or welding at right angles. The right-angle jigs provided with this clamp make your projects more efficient and precise.

Not only is this clamp a practical tool, but it also makes a unique and thoughtful gift for men, fathers, husbands, and woodworkers. The clamp comes with a one-year warranty.

Pros

- Made of high-quality aluminums alloy.

- Anodized red surface is anti-rust and corrosion-resistant, ensuring durability.

- Easy to use and securely holds pieces together.

Cons

- Limited in size, may not be suitable for larger woodworking projects.

3. SCDGRW 2 Pack corner clamps

They are made from high-quality materials, specifically aluminums alloy die-casting. This construction ensures excellent durability and a well-built design, guaranteeing a sturdy and long-lasting product.

The maximum adjustable clamping range of these corner clamps for woodworking is approximately 2.68 inches or 68 millimetres. The jaw width measures 3.74 inches or 95 millimetres, while the jaw depth is 1.4 inches or 35 millimetres. With such dimensions, these clamping squares can accommodate a variety of large objects, including steel rods, metal tubes, wood, and thick glass.

It features an ergonomic handle covered with rubber to provide a comfortable grip. It minimizes fatigue during long periods of use. The anti-skid handle ensures that users can securely hold the clamps without worrying about them slipping out of their hands. These clamps are designed with a 90-degree corner. The corner clamps ensure that your workpieces are securely held in place. They are preventing any movement or shifting during the clamping process.

Installation is made easy with the best clamping squares. The single-handle jaw of these woodworking clamps can be rotated in two directions, making it more convenient and precise. This versatility allows for a wide range of applications and ensures that the clamps can be used for various woodworking projects.

In addition to woodworking, these clamps can be used in other tasks such as welding, framing, drilling, doweling, making cabinets, and installing furniture. Their multi-functionality makes them a valuable tool to have in your workshop.

Whether you need to secure pieces of wood for a picture frame or hold materials together during a welding project, that will help you achieve precise and professional results.

Pros

- Made from high-quality materials.

- Adjustable clamping range.

- Ergonomic handle with rubber grip.

Cons

- May not be suitable for extremely large or heavy objects.

4. Jorgensen 6″ Spreader/Bar Clamp Set

These clamping squares are made from a combination of plastic and high-carbon steel materials. They are designed to provide maximum strength and durability for all your clamping needs.

With a throat depth of 2-3/8″ from the bar top of the pad, they offer a generous amount of space for secure clamping. The maximum opening capacity of 6″ ensures that you can easily accommodate various sizes of workpieces.

These clamping squares have a normal load limit of 150 lbs, making them suitable for light-duty applications. The bar is made from 1/8″ * 1/2″ plated, round-edge, high-carbon steel, providing a sturdy structure to withstand repeated use.

One of the key features of these clamping squares is the E-Z hold design. This design allows the clamps to be used in two ways – as a clamp or a spreader. This versatility allows you to tackle a wide range of projects with ease.

The advancing handle of this is made from glass-filled nylon, which provides a comfortable grip and ensures smooth and easy operation. This ergonomic design minimizes hand fatigue during extended use. The patented sliding head allows for higher clamping forces, providing up to 300 lbs of pressure. This innovative design ensures a secure and tight grip on your materials.

They also boast impressive features such as a 2-3/8 inch reach. This means they can easily accommodate a wide range of material thicknesses, making them versatile and suitable for various projects. The included soft and durable plastic pads ensure a secure grip while also preventing damage to your materials.

Invest in this today and experience the convenience and reliability. They provide in all your clamping and spreading tasks.

Pros

- Maximum strength and durability.

- Generous amount of space for secure clamping.

- Versatile design that allows them to be used as both a clamp.

Cons

- Suitable for light-duty applications only with a normal load limit of 150 lbs.

5. IRWIN QUICK-GRIP Clamps

Introducing the Best clamping squares – a versatile and efficient tool for your clamping needs. What sets these clamping squares apart is their non-marring pads. These pads not only provide a firm grip on your workpiece but also ensure that it remains scratch and scuff-free.

You’ll appreciate the quick-grip design of these clamping squares, thanks to the one-handed triggers. These triggers enable instant release of the clamps, allowing for swift and hassle-free adjustments.

Durability is a key feature of these clamping squares. Constructed with high-quality resin and reinforced with hardened steel bars, they are built to withstand heavy pressure. Say goodbye to worries about flexing or bending – these clamping squares are built to last.

With a remarkable force capacity of up to 140 lbs, these clamping squares can hold your workpiece securely in place. The even distribution of force, up to 150 lbs, ensures that your project remains stable and accurate.

Ease of use is another highlight of these clamping squares. They are specifically designed for clamping smaller workpieces and working in confined areas. Whether you are a professional or a DIY enthusiast, these clamping squares will simplify your clamping tasks.

Get your hands on the best clamping squares and experience the difference they can make in your projects.

Pros

- Non-marring pads protect the workpiece from scratches and scuffs.

- Quick-grip design enables swift and hassle-free adjustments.

- Durable construction with high-quality resin and hardened steel bars.

Cons

- Limited force capacity of up to 140 lbs.

Buying Guide for the Best Clamping Squares

To help you make an informed decision, we have compiled a comprehensive buying guide for the best clamping squares.

1. Material

They are made from either steel or aluminium. Steel squares offer excellent strength and durability, making them suitable for heavy-duty applications. They are resistant to bending or warping under pressure. On the other hand, aluminium squares are lightweight and easier to manoeuvre. They are ideal for lighter projects or those that require constant repositioning.

2. Size

Consider the size of the clamping squares based on the scale of your projects and workspace. Larger squares provide more stability and support, making them ideal for larger workpieces. Smaller squares are more versatile and easier to handle in confined spaces. Common sizes range from 3 inches to 12 inches. It is advisable to have a few different sizes in your toolkit for various project needs.

3. Clamping Mechanism

The most common ones include screw clamps, lever clamps, and quick-release clamps. Screw clamps offer precise and controlled tightening, but they can be time-consuming. Lever clamps provide quick and easy operation, perfect for repetitive tasks. Quick-release clamps allow for rapid adjustments and are convenient for projects that require frequent repositioning.

4. Jaw Design

The design of the clamping square jaws determines the type of materials they can effectively grip. Some clamping squares feature smooth jaws that work well with delicate materials like wood or soft metals to prevent damage. Other clamps have serrated jaws that provide a stronger grip for more robust materials. Consider the type of materials you will be working with and choose the corresponding jaw design.

5. Stability and Alignment

Squareness is critical for achieving accurate and precise joints, so choose clamps that have reliable mechanisms to maintain their 90-degree angle.

6. Accuracy

Look for squares that have a high level of precision and provide accurate right angles. Some clamping squares come with certification or calibration marks, ensuring their accuracy and reliability. It is also recommended to read customer reviews and check the product’s reputation for accuracy before making a purchase.

7. Durability

Look for squares made from high-quality materials that can withstand heavy-duty applications. Reinforced construction, such as reinforced edges or solid construction, can enhance the durability and longevity of the clamping squares.

8. Brand and Price

Reputable brands often provide higher-quality products and better customer support. It is still important to do thorough research and read reviews from other customers to ensure the product meets your specific needs. Compare prices from different brands to find a balance between quality and affordability.

9. Additional Features

These features can include measurement markings, extendable arms for larger workpieces, or adjustable angles for angular clamping. Consider whether these additional features are necessary for your projects or if you prefer a more straightforward and basic design.

Choosing the best clamping squares requires considering factors.

A Guide to the Top 5 Different Types of Clamping Squares and Techniques for Using Them

Right Angle clamp

A right-angle clamp is used in to hold two pieces of material at a 90-degree angle. It is adjustable and provides stability and accuracy during the joining or cutting process.

Techniques to Use

1. Use a piece of scrap wood or an additional clamp for added stability.

If the workpiece you are trying to clamp at a right angle is not thick enough or lacks stability, you can attach a piece of scrap wood.

2. Utilize a carpenter’s square or a speed square.

Carpenter’s squares or speed squares are specifically designed to assist in creating and maintaining right-angle clamps.

3. Use friction tape or sandpaper for added grip.

To prevent the right-angle clamp from slipping or shifting during clamping, you can wrap the contact points or jaws of the clamp with friction tape or sandpaper.

Corner Clamp

A corner clamp is used to hold two pieces of material at a right angle, such as when assembling corners of a frame or box. It applies pressure from multiple sides to ensure a tight and accurate joint.

Techniques to Use

1. Adjusting the Corner Clamp for a Perfect Square.

This step allows for precise and accurate clamping, resulting in perfectly squared corners.

2. Applying Even Pressure for a Secure Hold.

By doing so, the clamp will securely hold the workpiece at a 90-degree angle, preventing any movement during the glue or welding process.

3. Double-checking for Accuracy.

This final check ensures that the corner clamp has effectively maintained the desired square shape.

Bench Clamp

A bench clamp is a tool designed to consist of two jaws that can be tightened together using a screw or lever mechanism. Providing a secure grip on the object being worked on.

Techniques to Use

1. Optimize clamping efficiency with proper alignment techniques.

Use a straight edge or ruler to create a reference line that matches the desired angle or perpendicularity.

2. Enhance stability with the correct placement of clamping squares.

Place one clamping square on each side of the material, ensuring they are tightly secured to the bench clamp.

3. Increase accuracy with regular maintenance and calibration.

Inspect the clamping squares for any signs of wear or damage, such as dents, warping, or inaccurate measurement markings.

C-Clamp

C-clamp is used for securing and holding objects in place with its shaped “C” design and adjustable screw mechanism.

Techniques to Use

1. Use a rubber pad for added grip and stability.

This simple trick can ensure a secure grip on your workpiece and prevent any slipping or movement while clamping.

2. Opt for a double clamping method.

This method involves positioning the clamps on opposite corners of the square, exerting equal pressure on both sides.

3. Add a wooden block for precise alignment.

Place the block between the jaw of the clamp and the workpiece, ensuring it aligns perfectly with the square you’re clamping.

Quick-Grip Clamp

It functions by using a lever or trigger mechanism to quickly tighten or release the clamp’s jaws. It provides a secure grip on the object being held.

Techniques to Use

1. Utilizing Auxiliary Support. This will help minimize any potential sagging or flexing, ensuring precise and square clamping every time.

2. To apply the adjustable jaw design on the Quick Grip clamp for versatile clamping. The clamp’s jaws can be adjusted to accommodate different sizes and shapes.

3. Utilize the quick-release lever for efficient adjustments. This feature enables swift and accurate clamping, saving valuable time and effort.

Frequently Asked Questions Answered

1. Are Clamping Squares Worth It?

Whether or not they are worth it depends on your specific needs and budget. If you frequently work on projects that require precise angles and corners. Investing in clamping squares can be a good idea. If you only occasionally need to ensure square corners, you may be able to achieve similar results using other techniques or tools.

2. What are the Two Methods for Testing That a Frame in the Clamps is Square?

The two methods for testing that a frame in the clamps is square are:

Diagonal Measurement

This method involves measuring the diagonals of the frame using a tape measure or ruler. The diagonals should be of equal length if the frame is square. If they are not equal, adjustments can be made to the clamps or frame to ensure squareness.

Corner Angle Measurement

This method involves using a square or a framing square to check the angles at the corners of the frame. The square is placed against two adjacent sides of the frame. If the angle measures exactly 90 degrees, then the frame is square. If the angle is less or greater than 90 degrees, adjustments can be made to achieve squareness.

3. Are Spring Clamps Better Than Hose Clamps?

It depends on the specific application. Spring clamps are generally easier to install and remove but may not provide as secure or tight of a grip as hose clamps. Hose clamps are typically more durable and provide a stronger seal.

4. How Do You Clamp a 2×4 at 90 Degrees?

To clamp a 2×4 at 90 degrees, you will need a pair of woodworking clamps. First, position the 2×4 on a flat surface such as a workbench. Ensuring that one edge is against the surface and the other edge is perpendicular to it. Then, place one clamp near the end of the 2×4, aligning it with the 90-degree angle. Tighten the clamp securely to hold the 2×4 in place.

Next, use the second clamp to secure the other end of the 2×4, still ensuring it remains at a 90-degree angle. Tighten the second clamp firmly, making sure the 2×4 is securely held in the desired position. This clamping technique is commonly used in woodworking projects to ensure precise angles and proper alignment.

5. What Two Types of Clamps are Recommended for Clamping Up a Panel?

Two types of clamps that are recommended for clamping up a panel are bar clamps and pipe clamps. Bar clamps are versatile and commonly used for woodworking projects. They have a long adjustable bar, which allows for clamping larger panels. Pipe clamps, on the other hand, are used for clamping panels with irregular shapes or edges, as the pipes can be positioned to match the contours of the panel. Providing even pressure along the entire surface. Both types of clamps are effective in securing panels during glue-up or assembly processes.

6. What is the Most Useful Clamp Length?

The most useful clamp length will depend on the specific application and the size of the objects being clamped. A commonly available and versatile clamp length is around 6 inches to 12 inches (15 cm to 30 cm). This size range can be useful for a wide range of woodworking, metalworking, and other general clamping tasks.

7. What is The Best Steel for Clamps?

The best steel for clamps is typically considered to be stainless steel. Stainless steel is highly resistant to corrosion and rust. It also has excellent strength and hardness properties, ensuring that the clamps can securely hold and grip objects without bending or deforming. Stainless steel resists high temperatures, making it suitable for various applications and environments.

Conclusion

If you want value for your money, prioritize clamping squares that offer a combination of durability. By investing in the best clamping squares, you can ensure that you have a reliable tool that will help you achieve precise and professional results for days to come.